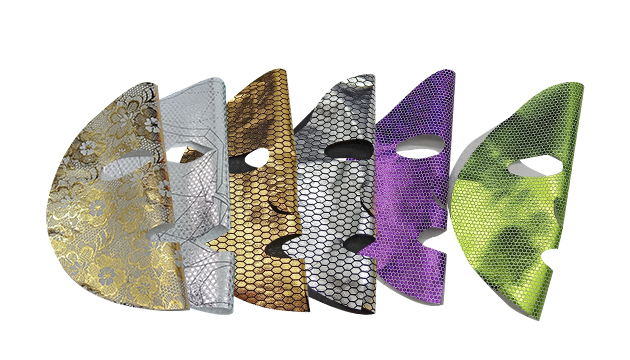

PROYONS has only done one thing in the past 10 years: committed to developing differentiated mask consumables and mask materials. We continue to work hard to make mask consumables and products meet the needs of brand image and customer market planning. We not only provide product matching solutions for global customers, but also work together with customers to firmly follow the attractive manufacturing development route.

Today, our products have been recognized and supported by our customers from one-stop worry-free services such as consumables OEM development, product design, packaging material selection, after-sales service tracking and follow-up product upgrade tracking. We believe that even if the same mask fabric is matched to different beauty materials, it can produce different user experience. Therefore, we have always insisted that different types of mask products should be given different manufacturing charms and using charms. Not just the difference between brands or bags.We are willing to provide product and service support for different customers with a stable supply chain, excellent product manufacturing solutions, professional manufacturing advantages ,quick-response after-sales service , seamless product follow-up upgrade technical reserves. Let every customer feel the charm of PROYONS global manufacturing.