Mask fabric sheet

Mask fabric sheetEOM/ODM process

+ SEE ALLAt present, we have 4 automatic cutting production lines. Full computer programming cutting control, can rotate the cutter head 360 degrees. The manufacturing workshop adopts the design of 300,000-class clean workshop. The production area of the whole workshop is equipped with ultraviolet equipment and ozone generator. In line with the "China Disposable Sanitary Disinfection Products Production License". The cutting of non-woven fabrics such as dry mask fabric can meet the requirements of 3-layer composite cutting at the same time. At the same time, we provide free pattern design and proofing services for various finishing products such as printing, compound bronzing, post-processing of freeze-dried powder, and micro-current mask fabric.

Finished facial mask

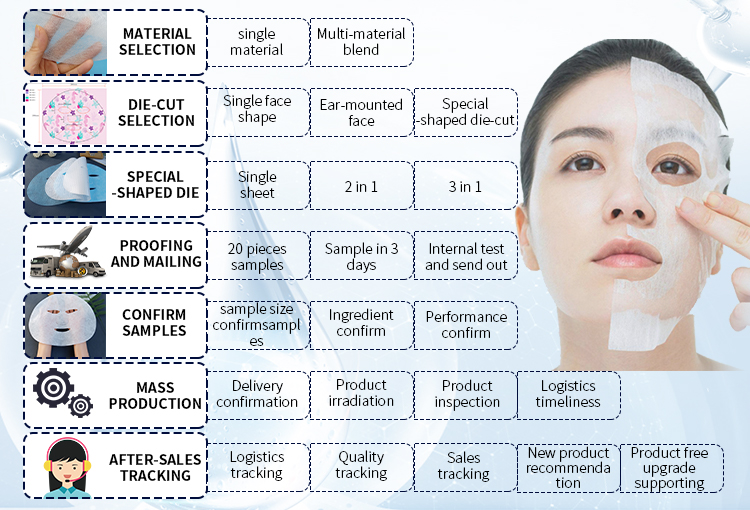

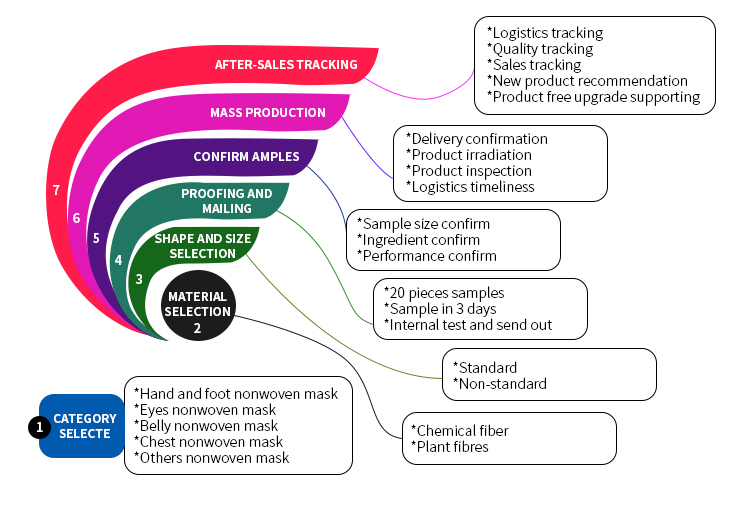

Finished facial maskEOM/ODM process

+ SEE ALLWe have more than 100 mature mask body formulas. When the customer provides the material formula, we will carry out the preparation and proofing within 48 hours. More than 200 kinds of substances such as niacinamide, single peptide substances, polypeptide substances, sodium hyaluronate, fusiformis extract, honey extract, cactus extract, selaginella extract, etc. are always in our stock. From packaging material design, material selection, formula design to proofing, testing and proofing of finished masks with different formulas can be completed within 7 days, and samples will be mailed to the customer's detailed address.

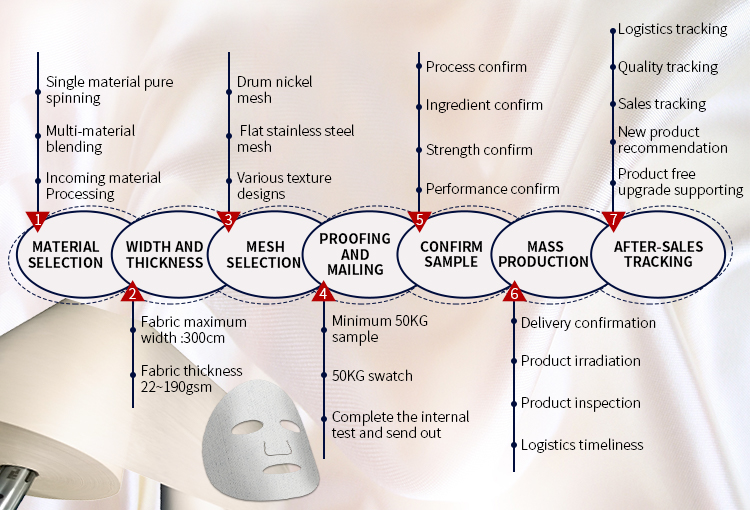

Spunlace nonwoven

Spunlace nonwovenEOM/ODM process

+ SEE ALLWe have been committed to developing spunlace non-woven fabrics with different materials and functions. From natural fibers (plant spinning instead of worker spinning) to pulp foil spinning of various plant extracts, every year we develop at least 2 new fiber materials with skin care benefits for the manufacture of spunlace nonwovens. At the same time, we are also innovating the manufacturing technology in response to the needs of different customers, so that the feel, softness, moisturizing performance, sticking performance, anti-deformation ability, environmental degradation and other aspects of the cloth can be individually matched to different needs and use effects.

Nonwoven products

Nonwoven productsEOM/ODM process

+ SEE ALLIn the manufacture of various nonwoven products such as compressed facial masks, compressed towels, hand and foot masks, dry wipes, makeup remover cotton, etc., our monthly output exceeds 800 sets. We have 15 sets of compressed facial mask and compressed towel equipment, 2 sets of ultrasonic manufacturing equipment for hand and foot mask, 1 production line for dry and wet wipes and 1 automatic production line for cleansing cotton.

Production equipment overview

Explore2 spunlace non-woven production lines; 4 production lines for mask fabric sheet processing; 2 automatic mask filling production lines; 15 sets of mask fabric folding machines; 10 sets of mask fabric and towel compressed equipment; 1 automatic printing production line; 1 micro-current screen printing equipment; R&D team 10 employees,Production team 90 employees,Sales team 10 employees;

Experimental testing equipment overview

Explore1、 Electronic balance; 2、 Moisture titrator; 3、 UV spectrophotometer ; 4、 Fourier transform infrared spectrophotometer; 5、 Tablet meter; 6、 Gas chromatograph; 7、 Hydrogen, nitrogen, air generator: used with gas chromatograph; 8、 High performance liquid chromatography: qualitative and quantitative analysis of cosmetic raw materials and semi-finished active ingredients, various preservatives, sunscreen whitening ingredients, etc; 9、 Ultrasonic cleaner; 10、Oscillator: sample pretreatment for high performance liquid chromatography; 11、Biochemical incubator; 12、Oven; 13、PH meter; 14、Viscometer; 15、Melting point apparatus; 16、Abbe refractometer; 17、Sterilizer; 18、Water bath pot: used for drying, concentration, distillation, impregnation of chemical reagents and biological products, and can also be used for water bath constant temperature heating and other temperature tests; 19、Muffle furnace: Determination of ash content of cosmetic raw materials.

Charming Facial Mask Designer

ExploreWe continue to innovate and improve product manufacturing technology and quality, and use cutting-edge technology and meticulous services to continuously meet customers' needs for the ultimate experience of facial mask products.

Our goal is to give mask manufacturing a unique brand charming.